Solar-assisted heat pump for biomass drying – pv magazine International

Scientists from Finland have built an experimental system that allows the drying of woody biomass with solar thermal energy and a heat pump. They claim PV may play a complementary role in the proposed setup.

Researchers from the VTT Technical Research Centre of Finland have demonstrated a hybrid system for drying woody biomass that utilizes both solar thermal energy and a heat pump.

“We have indeed considered the possibility of powering the heat pump with PV,” corresponding author Tomi Thomasson told pv magazine. “However, relying solely on PV is not deemed feasible, given the limited solar hours in the Nordics. Grid electricity is essential to ensure an adequate number of annual operating hours and sufficient drying quantities.”

“We recognize that PV can play a complementary role in this setup,” Thomasson added. “With local PV production, we could avoid electricity transmission costs and potentially increase the feasible operating hours for the heat pump. Furthermore, local PV production could help reduce investment risks associated with the price volatility in the electricity market.”

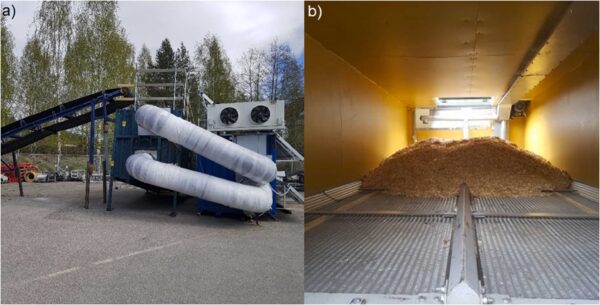

The scientists built an experimental setup consisting of two freight containers. In the first, they installed a 24 kW heat pump, a condenser, an evaporator, a heat recovery unit, a heat exchanger, and 12 flat-plate solar heat collector modules. The second container consists of a drying chamber for fresh wood chips in size classes P16 and F15.

“The main role of the heat pump is to remove moisture from the drying air, but it can also provide additional heat at the beginning of the drying process since, to work efficiently, the drying air temperature must reach at least 20 ◦C before switching the heat pump into a drying mode,” they added.

Image: VTT Technical Research Centre of Finland Ltd, Energy Reports, CC BY 4.0 DEED

Under its hybrid mode, the system uses closed-loop drying, where the same air is circulated through the system. If solar radiation is also available, the thermal collectors provide an additional heat input. In its solar mode, the system only uses collectors to dry the biomass.

The scientists conducted 34 hybrid experiments totaling 316 hours on the setup in 2021 and 2022 in Finland.

The setup results showed that hybrid drying results in higher and faster drying rates. The average drying rates were 32.96 kg/h with solar drying. However, as the heat pump was powered from the grid, the decreased drying duration was enabled by increased electricity consumption.

The heat pump needs 8.24 kW to dry the wood, while the solar mode requires 1.45 kW for the fan used for airflow. “Due to the improved drying rate, the specific electricity consumption in hybrid operation mode is only 45% higher at 0.26 kWhe/kg compared to 0.18 kWhe/kg,” the academics stated.

The researchers then used some collected data points to build a model that can assume drying rates and power consumption under different operating conditions. Those estimation methods, which used a gradient boosting model and a multiple linear regression model, received an average mean absolute error (MAE) of 0.27 (deviation of 5.9%) for the drying rate and an average MAE of 0.88 (deviation of 8.9%) for the power consumption.

Then, the researchers fed the results of this model, along with weather and market data, into an optimization model.

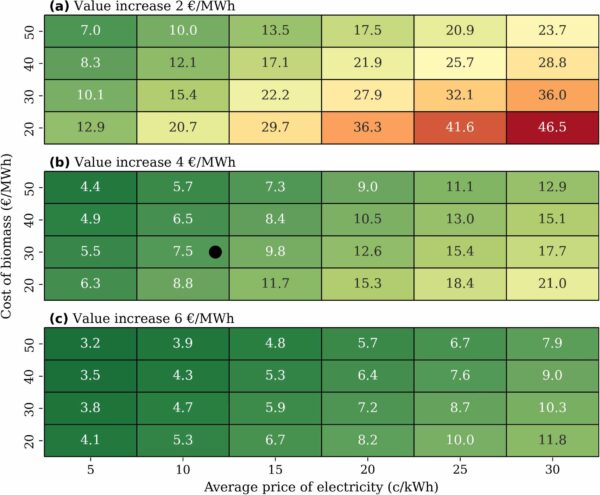

Image: VTT Technical Research Centre of Finland Ltd, Energy Reports, CC BY 4.0 DEED

The optimization model gave results in the form of payback time for the system, considering three varied parameters and their combinations: the value increase of biomass in drying, the cost of biomass, and the average price of electricity. The researchers focused their analysis on the terms of a pilot-scale system and a commercial system.

“For the pilot-scale unit, the investment cost was determined based on the actual procurement cost, while for the commercial unit, the cost was estimated considering the economies of scale and a reduced instrumentation requirement compared to the pilot-scale unit,” they explained.

The research found the payback time for the commercial scale project to be 7.5 years, while it was 10.1 years for the pilot scale. When considering a 30% investment subsidy, those rates fell to 5.3 years and 7.1 years, respectively. When considering biogenic CO2 compensation, the payback times decrease to 4.8 and 6.5 years.

“Operating flexibility is required to achieve the estimated economic feasibility,” the research team explained. “The flexibility potential decreased in colder temperatures due to an exponential increase in required preheating time. Based on the economic analysis, the benefit of operating flexibility increases with the electricity price, as the optimal operation shifts from nearly constant hybrid drying towards increased solar drying and nonoperating hours.”

The system was introduced in the paper “Experimental and techno-economic analysis of solar-assisted heat pump drying of biomass,” which was recently published in Energy Reports.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.